Need a standalone or network solution to meet your QA reporting goals?

- Spending too much time managing and downloading test recipes to a variety of machines?

- Need an audit trail for recipes, limits, and results?

- Having problems collecting and managing data from tire test machines provided by a variety of vendors?

- Want to direct tire flow based on manufacturing data?

- Consuming too many IT and engineering resources to implement out-of-the box solutions?

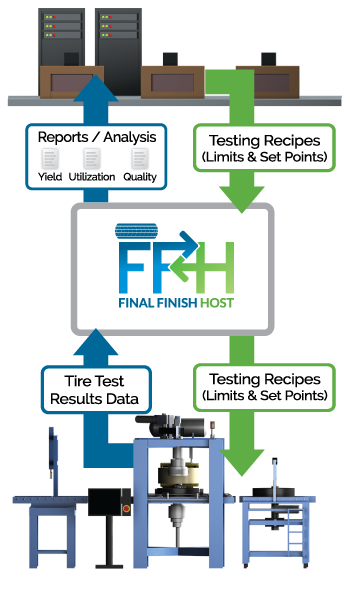

FFH converts tire test results into actionable data. The basic system includes:

FFH collects, summarizes, and stores test results for tire uniformity, geometry, and balance machines.

Use a web browser to design recipes that include test sequence, grading limit, and machine setup parameters (such as servo positions), then download the recipes directly to the final finish machines.

A variety of graphic and tabular reports display uniformity, repeatability, and machine utilization in PDF format.

Like other Poling Group products, FFH provides extra value because we customize it to fit your particular machines, operations, and business requirements. We developed FFH specifically for tire manufacturing final finish to provide the data and reporting you need to satisfy both external and internal customers.

Field Proven

FFH has been customized for and successfully implemented at several global tire companies.

Whether you need a standalone or building block solution, FFH can help you reach your QA goals.

FFH has been customized for and successfully implemented at several global tire companies.

- Provides a single access point to control customer specs, analyze data, view machine performance, and schedule machine preventive maintenance

- Easily collects data on a 24/7/365 basis with transaction volumes exceeding 260,000 per day

- Combine FFH with existing proprietary or legacy systems to derive additional benefit from them

- Integrate FFH with a material handling system so you can track and then route tires according to real-time and historical process data

Whether you need a standalone or building block solution, FFH can help you reach your QA goals.

- Completely integrated with Poling Group's TTOC uniformity machine controller, FFH also supports a variety of other final finish testing machines

- Supports bar coded material handling

- Zero footprint architecture using a Linux server

- View, save and print PDF reports at any PC

- Summary data compiled across many machines

Data Collection and Reporting

Data Collection and Reporting- Collect and store test results from different machines provided by different vendors.

- Maintain individual and summarized test results in a database specially designed for optimal reporting performance.

- Choose naming convention and unit of measure preference for measurements and reports.

- Select preferred distribution for each measurement (Normal vs. Weibull)

- Choose tabular or graphic reports.

- Authorize report and management applications on an individual user basis.

- We can integrate final finish data to existing order and combine final finish data to existing order and shop floor databases

Centralized Recipe Management

Centralized Recipe Management- Save time - eliminate loading recipes via data entry or laptop.

- Decrease error – manage a single source of truth for each recipe sent to multiple machines.

- Simplify management – each recipe contains setup parameters for different machines (balance, geometry, uniformity) and functions (testing, grading, marking, sorting).

- Add accountability – FFH provides recipe versioning and a quick way to view differences between versions.

Dynamic Production Monitoring

Dynamic Production Monitoring- Improve visibility - real-time production counts and status available from any desktop.

- See productivity – color-code recipes to identify customer-specific production or non-customer processing (like tooling checks). Red reserved to indicate time-out exceeded for receiving test result data.

- Simplify management – each recipe contains setup parameters for different machines (balance, geometry, balance) and functions (testing, grading, marking, sorting).

CTI, A POLING GROUP COMPANY

Founded in 1978, CTI has been a valuable resource for large industries. Since 2001, we've expanded the capabilities of Poling Group tire equipment, including uniformity and geometry testing machines.

©2025 Commercial Timesharing, Inc. All Rights Reserved

CTI is a Poling Group company.